Do you have new requirements for the function or application of adhesives and thermal management materials? XG Electronic Adhesives takes you on an amazing journey of product design and development!

Principles Of Customization

In-depth study of customer product application requirements and process technology, by professional R & D team customized more than the demand for high-performance products and overall solutions, so that the adhesive products are more suitable for the actual application of the customer to help customers to improve the quality of the process, reduce the cost of consumption, and to achieve rapid delivery.

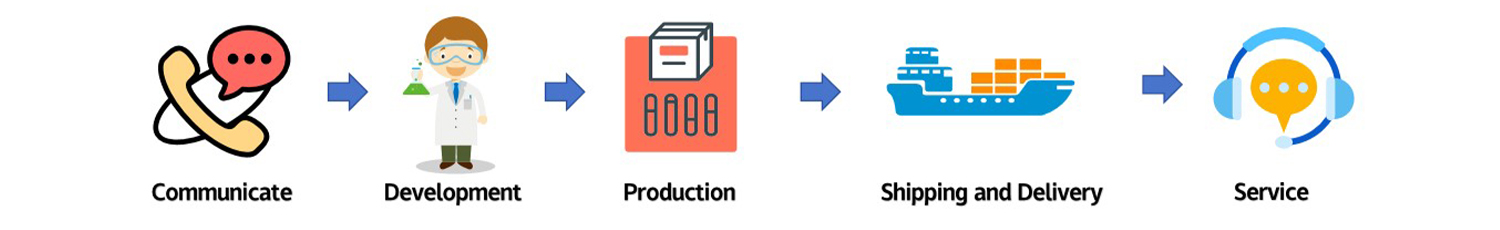

Custom Development Process

1.1 Understand customer needs

Communicate fully with customers by email, phone, video, visit and so on, to understand customer needs thoroughly;

1.2 Determine the solution

Research multiple solutions in-house and determine the final solution after recommending it to the client for selection;

1.3 Accounting for costs

According to the solution for the cost estimate calculation, the customer agrees to carry out the development.

2.1 Developing product formulations

Based on a large number of tests, the formulation of the solution is initially completed and samples are made;

2.2 Complete performance testing

According to the customer’s requirements for the product, all the relevant tests are carried out on the samples to ensure that the performance of the product meets the requirements before handing them over to the customer for testing;

2.3 Deliver samples to customers for testing

Produce the samples required by the customer and hand them over to the customer for verification testing;

2.4 Trial effect assessment

Follow up with the customer to verify the effect, determine the performance parameters and application process in line with the sample, sealed samples to be retained for control;

2.5 Negotiation of quantitative

According to the samples confirmed by the customer, communicate the product supply price, and then supply according to the procurement contract.

3.1 Determine process standards and testing standards

According to the quality control system of the product, establish the production production operating instructions, determine the key testing indicators, and develop shipping inspection standards;

3.2 Conduct small and medium batch trial production

Carry out multiple small and medium batch trial production, and track the results of trial production to improve to the most satisfactory state of the customer;

3.3 Fixed sealing of formulas and production processes

Formulation and other technical information can not be changed without customer notification of the formula and production process.

4.1 Multiple shipping methods

Match customers with one-stop shipping, railroad transportation, express, air transportation and other

Delivery service, safe and punctual with rationalization of costs.

5.1 Professional after-sales service

The company has a professional technical service team, at any time to provide professional after-sales service, eliminating the customer’s worries;

5.2 Ensure application stability

We analyze the application results of the products together with the customers and form application operation documents to ensure the application stability of the products.