Adhesive solutions for headlamps

Headlights are used to provide illumination for the driver to ensure driving safety, as well as to communicate with other vehicles and pedestrians through light signals. Lamps are very complex, a variety of types and high technical difficulty. Due to the working characteristics of the lamps, the need to use special adhesive sealant lamps, need to have a certain degree of flexibility, vibration resistance and adhesion, play a shock absorbing sealing waterproof role.

Silicone adhesive sealant used in automotive lamp adhesive sealing, excellent chemical resistance, good adhesion, can resist the environment of moisture, dirt and other unfavorable components of the erosion, at the same time for the lamp to reduce the mechanical, thermal shock and vibration caused by mechanical stress and tension. Automotive lamp adhesive sealant corona resistance, good insulation, excellent resistance to outdoor aging performance, in the lamps and lanterns in a closed environment, low volatility and can withstand high temperatures for a long time, is the lamp adhesive sealing of choice.

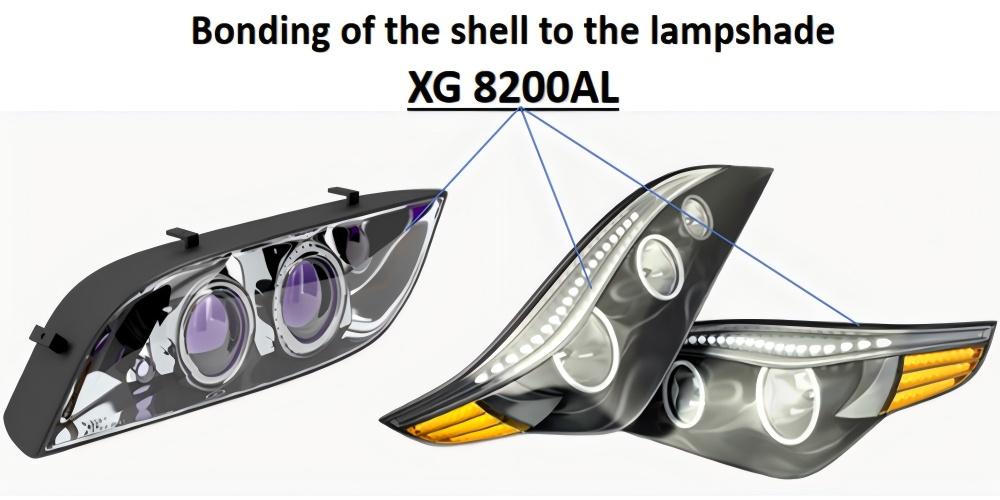

XG Electronic Silicone provides reliable materials for lamp bonding, using automotive lamp bonding sealant XG-8200AL to bond the lamp housing and lampshade, with good adhesion and sealing performance, and after curing, it can form a layer of waterproof and dustproof barrier to protect the interior of the lamp from external environmental erosion, especially in the humid or harsh environments with excellent performance, to protect the internal structure of the lamp and optical components, to ensure the normal operation and prolong the service life of the lamp. It protects the internal structure and optical parts of the lamp, ensuring the normal operation and prolonging the service life of the lamp.

XG provides advanced adhesive materials to ensure stable and reliable operation of the lights.

👉 For this application, we recommend using our specialized potting compounds to ensure long-term protection.